XL Engineering Trading was established in 1990 and operates from our purpose-built facility that enables us to deliver rapid short batch and complex fabrications to automotive, security, civil nuclear, agricultural, maritime, construction and heavy engineering sectors. We also have a ‘design assist’ capability to aide customers in product development and improvement projects.

Over

Thirty Years

of Engineering

Excellence

what we do

Our Services

We can supply anything from laser profiled sheet metal parts to complex metal fabrications.

Precision Laser Cutting

Laser cutting is quick, clean and accurate as well as having many applications across a variety of sectors.

Press Brake Forming

XL Engineering and its CNC and Press Work processes ensure we produce high quality components from a wide range of materials.

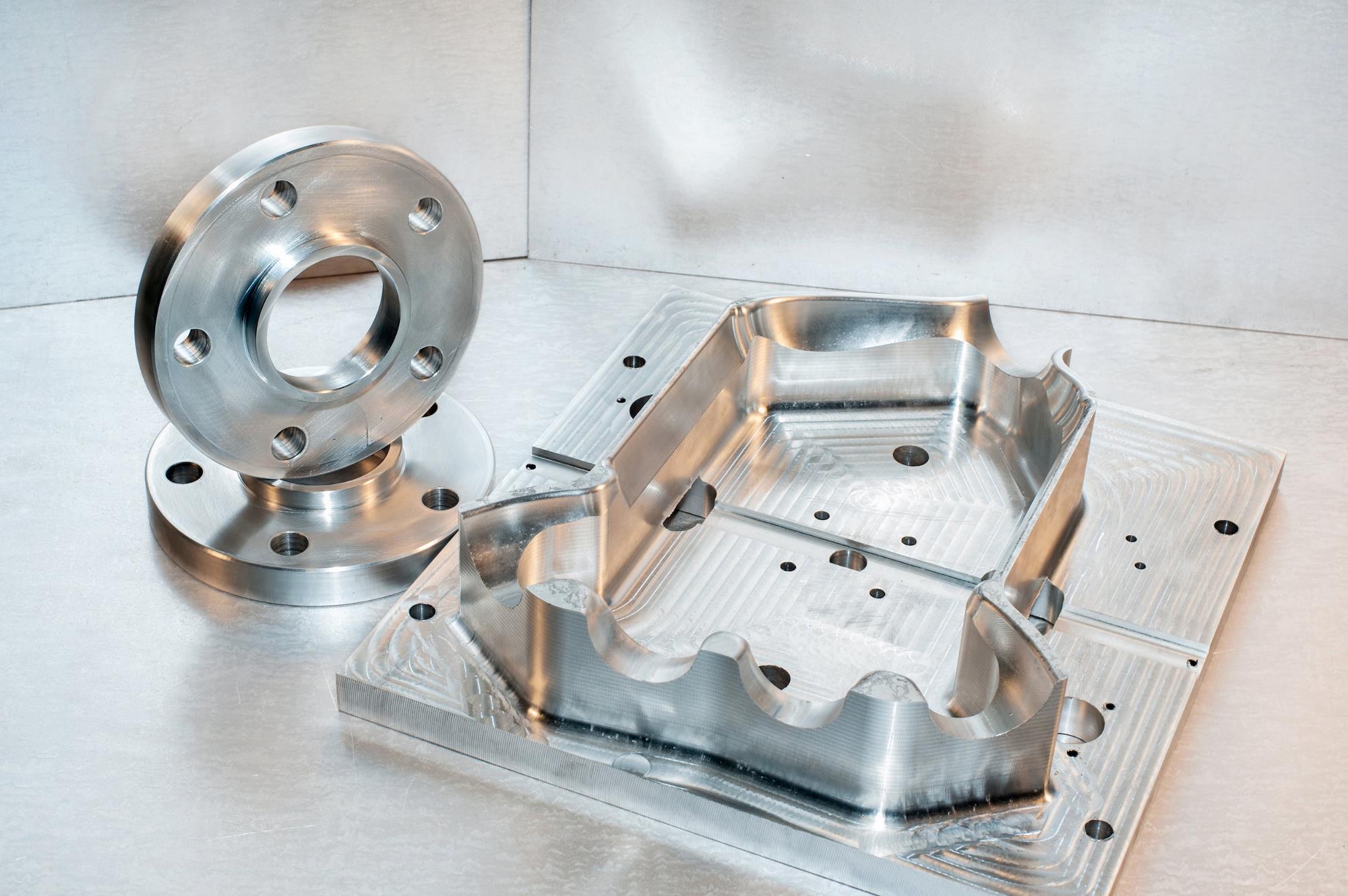

Machining

At XL Engineering we are able to supply fabrication work which includes both sheet metal work and machined parts.

Fabrication

XL Engineering has a highly skilled and time served workforce, using our own precision jigs.

Sawing &

Pipe Bending

We offer precision sawing services for a wide range of materials. Our advanced sawing equipment allows us to cut through even the toughest materials with accuracy and speed. Our skilled fabricat...

Finishing

As many of the components XL Engineering produce are exposed to extreme weather conditions, lasting protection is essential.

If you'd like to know more about XL Engineering, to discuss a project, or ask us about anything – we'd love to hear from you.

showour benefits

Why Choose Us?

01 Our reputation for the highest quality work coupled with excellent customer service.

02 4 Decades

of experience.

03 Our expert personnel and purpose-built facilities are adaptable to your needs.

Work with

XL Engineering

We have the capabilities to assist with design and prototyping,

producing small batch work. Call now!

how we do it

The

Process

Design Assist

Sheet Metal

Laser Cutter

Press Machines

Welding / Fabrication

Clean

Finishing

ISO

Quality and Governance Standards

Quality Standards are certified at every stage of the manufacturing process. Our Quality Management System has been approved since 1992 by NQA Ltd and we are now complying with BSEN ISO 9001:2015. We are also proud to have achieved Environmental Management System ISO 14001:2015.

Governance. We have been granted ‘Fit for Nuclear’ status. This recognises that our assurance framework meets the standards expected for supplying the civil nuclear industry, this being: new build, operations and decommissioning.

If you require further information please don’t hesitate to contact us.